Embrace Innovation

Technology Innovation

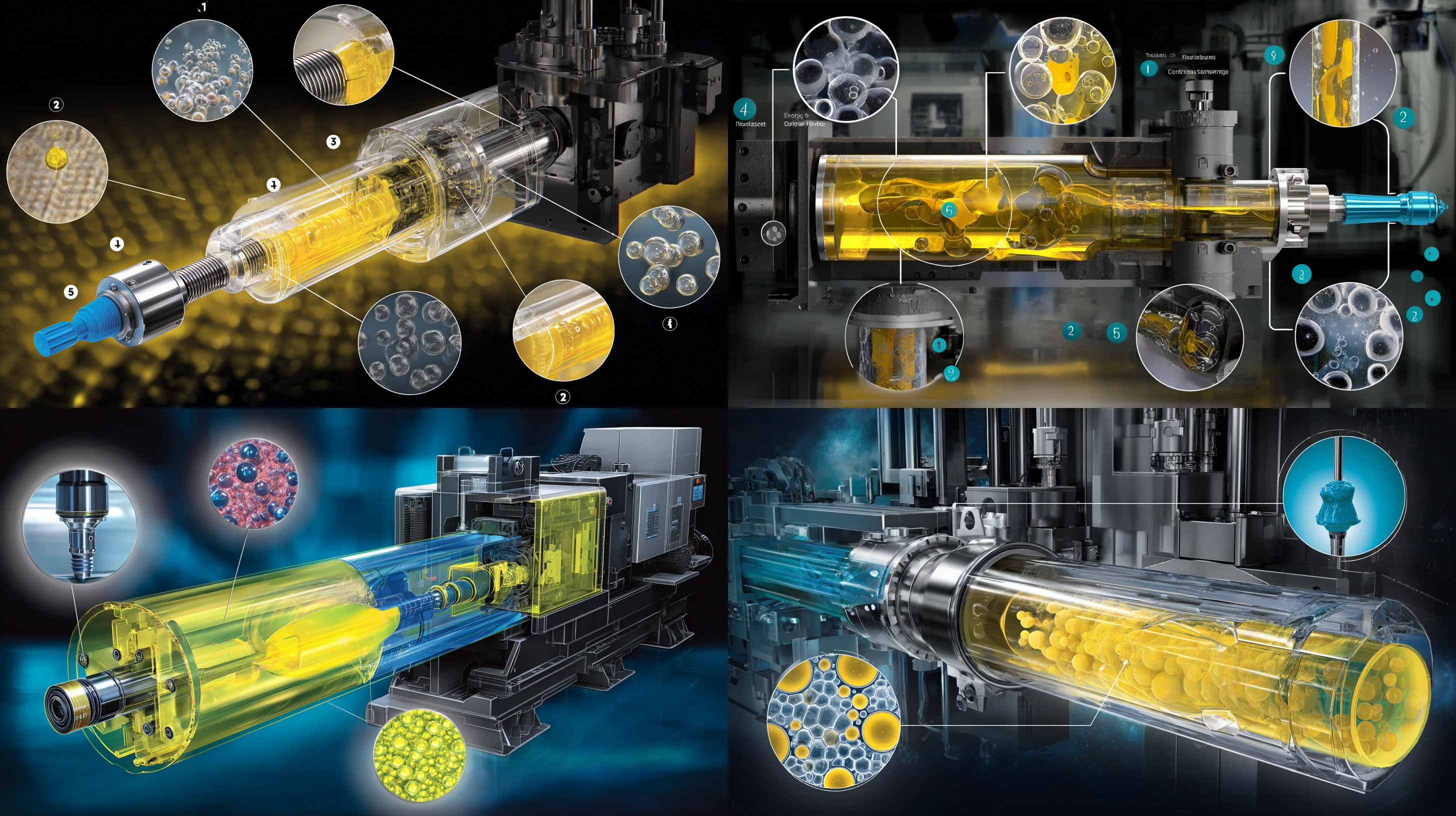

Microcellular Foaming Technology

Microcellular foaming technology?uses physical blowing agents (like N? or CO?) to create a microcellular structure during injection molding. Its core principle involves dissolving a supercritical fluid into a polymer melt. Upon injection, a sudden pressure drop nucleates bubbles, which solidify into a uniform microcellular foam during cooling.

Advantages:

Lightweight design

High dimensional precision

Reduced molding cycle time

Elimination of surface sink marks

Lower clamping force required

Applications:

Automotive, electronics, medical manufacturing and other industries

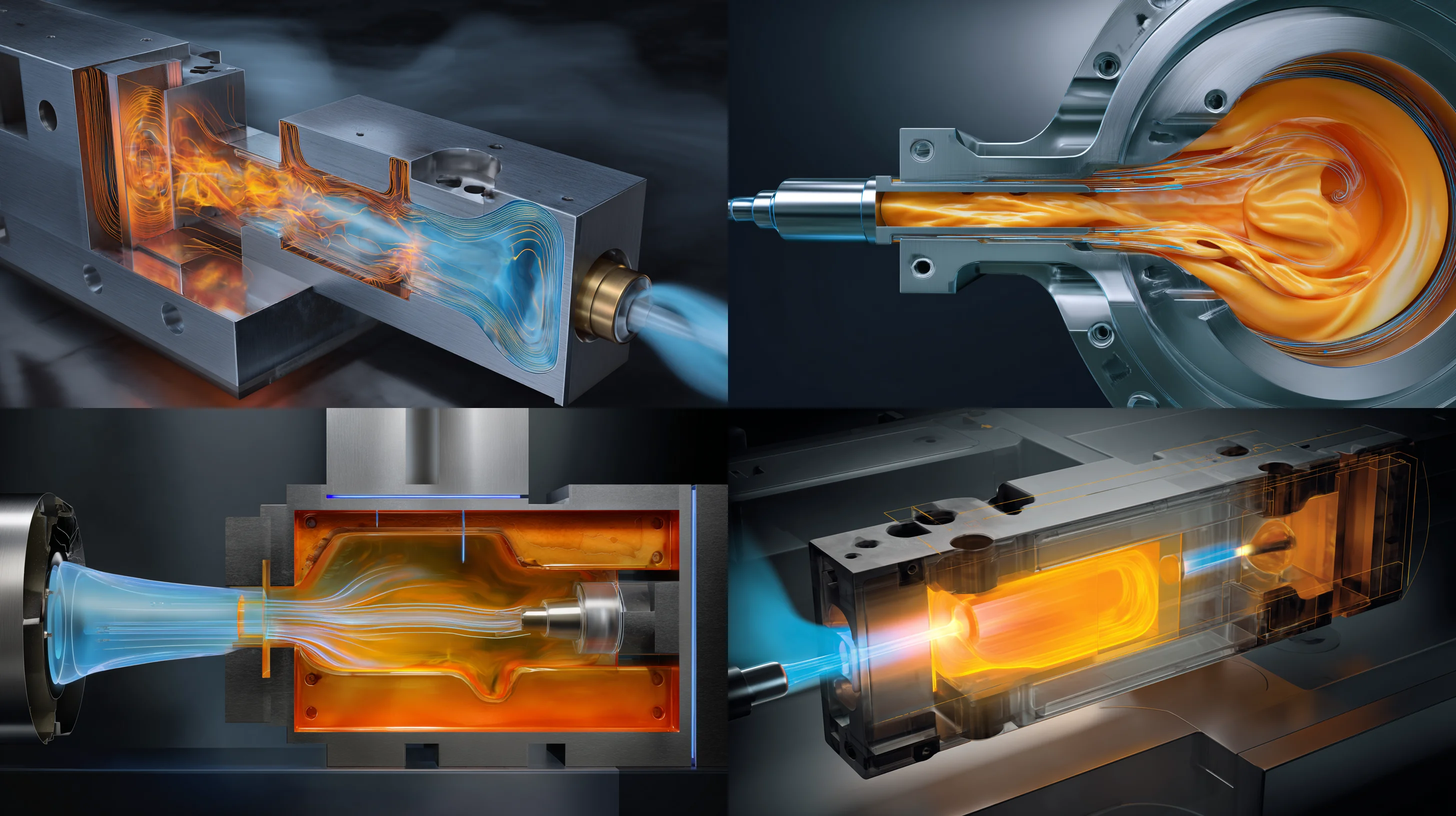

Gas-assisted injection molding (GAIM)

Gas-assisted injection molding (GAIM) is a process that optimizes injection molding by injecting high-pressure gas (typically nitrogen) into the polymer melt. It is primarily used to address defects such as sink marks and warpage in thick-walled parts.

Advantages:

Lower production costs

Improved surface finish

Greater design flexibility

Applications:

Automotive, home appliances, consumer goods and related industries

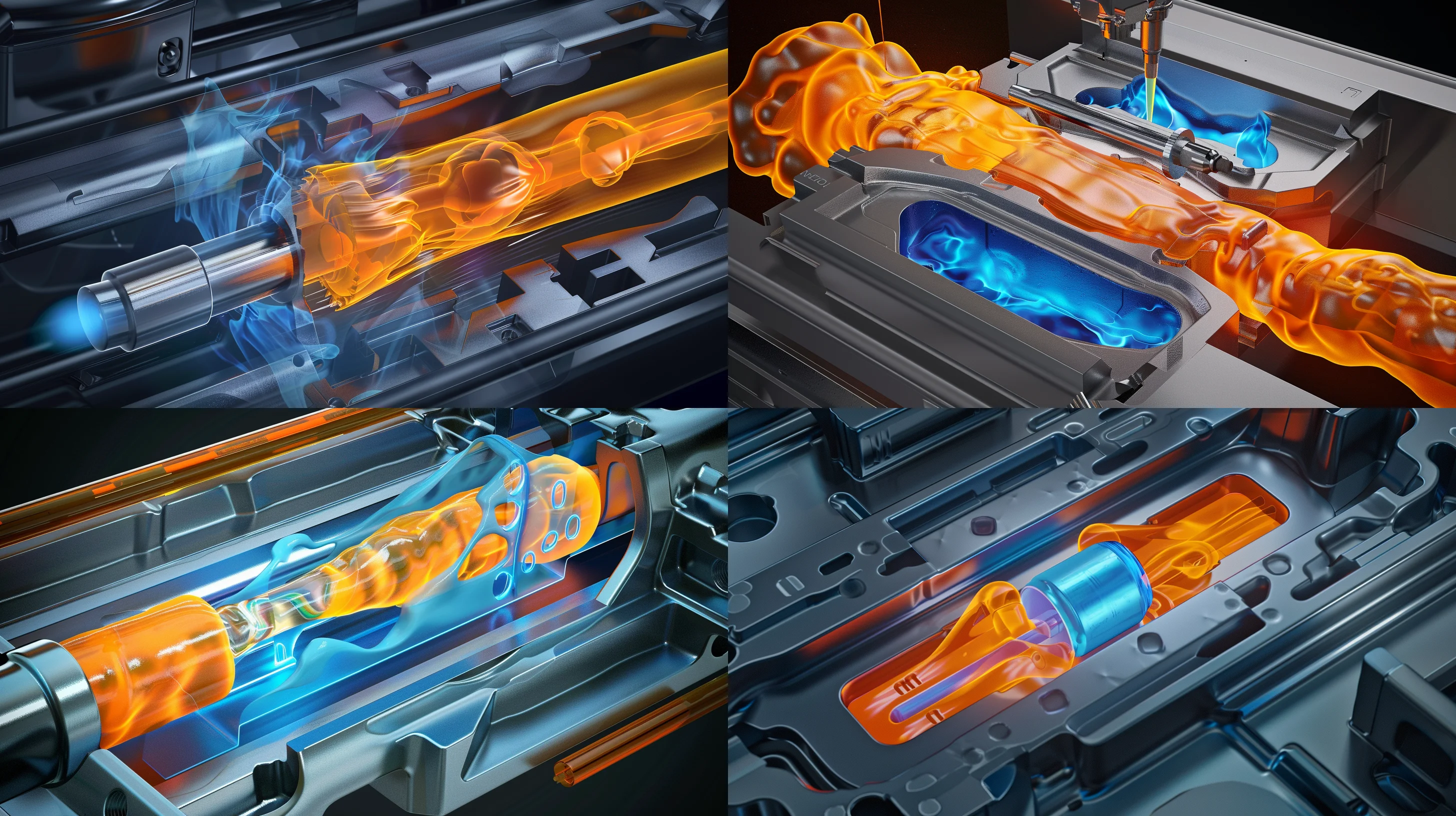

Thin-wall injection molding

Thin-wall injection molding is a precision molding process designed for parts with wall thicknesses less than 1mm or a flow length-to-thickness ratio (L/T) ≥ 100. It is primarily used to produce lightweight, high-precision miniaturized products.

Advantages:

Lightweight design

High dimensional accuracy

Reduces production costs by lowering part weight (material and molding costs)

Enhanced dimensional stability

Applications:

Automotive, consumer electronics, medical products and related fields

Low-pressure injection molding

Low-pressure injection molding is a forming process that injects molten plastic into a mold under low pressure (0.15–4 MPa). It is particularly suited for producing precision components with integrated skin-core composite structures.

Advantages:

High dimensional accuracy

Lightweight design

Environmentally friendly process

Improved production yield

Applications:

Automotive, electronic encapsulation, medical products and related fields

Talent Innovation

The dual-track system offers parallel advancement channels: the management track emphasizes communication, coordination and strategic decision-making, while the technical track focuses on technological innovation and problem-solving capabilities. This mechanism not only helps retain key technical talent by removing the barrier of management-track promotions but also enables specialists to stay focused on R&D, accelerating process innovation and iteration.

Management

Professional

Through the establishment of cooperation with universities, with the help of university talent advantage in-depth study of injection molding process technology innovation. At the same time, with the help of the university digital twin training system, the use of VR/AR simulation of high-risk operation scenes, reducing the cost of hands-on training of personnel.

Digital Intelligence Integration

Mold Production Dashboard integrates KPIs including annual output value, equipment yield, drilling capacity and machining tasks into a unified visual platform.

Key advantages

- Agile Capacity Control: Monitor drill utilization/OEE dynamically, auto-flag bottlenecks (e.g., <85% efficiency), accelerating task redistribution by 40%

- Data-Driven Forecasting: Sync machine output with annual targets, simulate delivery timelines proactively, achieving >95% accuracy in capacity planning

- Resource Maximization: AI-driven task scheduling based on equipment load cuts idle time by 30%, boosting average utilization to 92%+ and unlocking $500K+ annual capacity

By replacing heuristic decisions with real-time analytics, the dashboard elevates mold manufacturing to lean, delay-free production.